Oil Cooler Unit

KAUKAN Oil Chiller Features & Illustrations

- ±0.2°C Precision Temperature Control – Ensures machining accuracy

The temperature stability of machining equipment directly impacts processing quality. KAUKAN Oil Chiller Machines utilize a high-precision temperature control system, maintaining oil temperature within ±0.2°C. This significantly reduces workpiece errors caused by temperature fluctuations, enhancing product consistency and machining accuracy. - High-Efficiency Heat Dissipation – Prevents thermal deformation and maintains machining stability

During the machining process, the heat generated by operating machinery can cause thermal expansion of components, affecting precision machining results if not dissipated quickly. KAUKAN Oil Chiller Machines feature high-efficiency heat dissipation technology, ensuring stable oil temperature to prevent workpiece deformation or loss of accuracy due to temperature rise, thereby enhancing production efficiency. - Long-Term Operation – Reduces processing costs

A cooling system designed for long-term operation must offer high stability and low failure rates. KAUKAN Oil Chiller Machines incorporate durable components and high-performance design, ensuring stable operation even in harsh environments. This reduces maintenance needs, lowers downtime costs, and improves overall production efficiency. - Prevents Temperature Rise Impact – Extends equipment lifespan and enhances machine durability

Excessive oil temperature not only affects machining conditions but also accelerates the aging and wear of internal machine components. KAUKAN Oil Chiller Machines utilize precise temperature control to prevent rapid internal temperature rise, extending equipment lifespan while reducing maintenance and replacement costs. - User-Friendly Operation – Easy installation and maintenance

KAUKAN Oil Chiller Machines are designed with user-friendly operation and easy maintenance in mind. The intuitive control interface allows users to quickly get started, while the machine's structural design ensures easy access for maintenance. This makes servicing and component replacement more convenient, significantly reducing operating costs and maintenance time. - Intelligent Fault Warning System – Predicts issues in advance

To minimize losses caused by unexpected equipment failures, KAUKAN Oil Chillers are equipped with an intelligent fault warning system. This system alerts users to potential issues before they escalate, allowing for timely inspections and preventing minor problems from turning into major failures, thereby reducing the risk of production downtime. - Error Code Design – Enables users to quickly troubleshoot problems

When an abnormal condition occurs, KAUKAN Oil Chillers display a corresponding fault code, enabling users to quickly diagnose the issue and perform basic self-checks. This reduces the wait time for professional technicians, accelerates equipment recovery, and enhances production efficiency. - Eco-Friendly Refrigerant Design – Contributes to environmental protection

KAUKAN actively responds to environmental trends by developing oil chillers that utilize low-GWP (Global Warming Potential) eco-friendly refrigerants. These refrigerants effectively reduce carbon emissions during operation while maintaining optimal cooling performance. By minimizing environmental impact, KAUKAN Oil Chillers comply with international environmental standards. - Variable Frequency Energy Saving – Reduces power consumption by over 35%

KAUKAN Oil Chillers are designed with variable frequency compressors and intelligent energy-saving technology, automatically adjusting operation modes based on equipment load. This reduces unnecessary power consumption and achieves over 35% higher energy efficiency compared to traditional coolers, significantly lowering energy costs. - Customizable Specifications – Meets diverse industry requirements

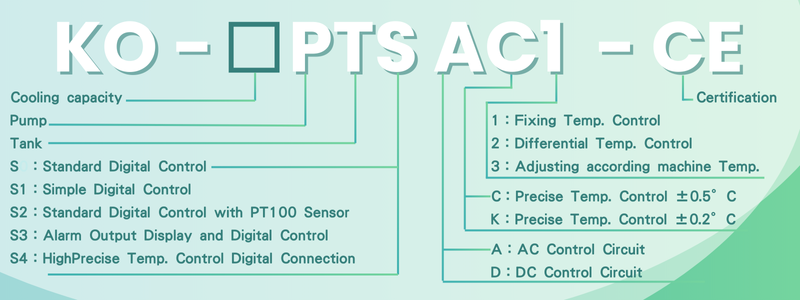

Cooling requirements vary across industries, and KAUKAN Oil Chillers offer customized designs to meet specific needs. Cooling capacity, oil circuit design, and installation methods can be tailored according to customer requirements, ensuring optimal compatibility with your equipment for maximum cooling efficiency.

* All features are configurable to best suit your operational demands.